Hebei Huaye Energy Saving Technology Co., LTD profile

Hebei Huaye Energy Saving Technology Co., LTD., located in Handan, a historic city, was established in 2008.

The company provides installation, maintenance and commissioning services for power engineering, energy saving and environmental protection technology, communication and automation control, fire engineering and metallurgical technology and engineering equipment.

Our company has professional production workshops and technical staff. The company has 5 departments and production workshops, covering an area of 500 square meters, advanced production equipment, complete testing equipment; The company has 30 technical employees, including 10 management and technical personnel, 20 equipment manufacturing personnel.

In 2017, the coke oven gas boiler anti-corrosion waste heat recovery technology independently developed by the company can reduce the smoke exhaust temperature of the current conventional boiler after combustion from 170 degrees to 110 degrees, saving a lot of heat energy for the enterprise, improving the power generation efficiency by 2%, and reducing carbon emissions! This technology has obtained the national patent.

Project overview

一、SRT -Steam Reheat Turbo-generating

Hebei Huaye Energy Saving Technology Co., LTD profile

Hebei Huaye Energy Saving Technology Co., LTD., located in Handan, a historic city, was established in 2008.

The company provides installation, maintenance and commissioning services for power engineering, energy saving and environmental protection technology, communication and automation control, fire engineering and metallurgical technology and engineering equipment.

Our company has professional production workshops and technical staff. The company has 5 departments and production workshops, covering an area of 500 square meters, advanced production equipment, complete testing equipment; The company has 30 technical employees, including 10 management and technical personnel, 20 equipment manufacturing personnel.

In 2017, the coke oven gas boiler anti-corrosion waste heat recovery technology independently developed by the company can reduce the smoke exhaust temperature of the current conventional boiler after combustion from 170 degrees to 110 degrees, saving a lot of heat energy for the enterprise, improving the power generation efficiency by 2%, and reducing carbon emissions! This technology has obtained the national patent.

Project overview

一、SRT -Steam Reheat Turbo-generatingThe technology uses preheated steam generated in the production process of iron and steel plants, ferroalloy plants and other enterprises to generate electricity. In the process of production, a large amount of saturated steam is produced due to the cooling of flue gas in the steelmaking converter, electric furnace, sintering machine and ferroalloy smelting furnace of steel rolling furnace. In this technology, the saturated steam is collected and heated into superheated steam through a special steam heating furnace, so as to improve the work capacity of the steam and introduce it into the steam turbine generator set for efficient power generation. Compared with the amount of gas consumed by heating steam, the power generation efficiency can reach more than 70%, which is incomparable to any steam turbine generation method in the world at present. The fuel used for the steam is derived from waste gas from the steel production process - coke oven gas or blast furnace gas.

In this project, the steam filter, voltage regulator, and special ICS intelligent control system are applied to achieve effective control of steam fluctuations, so as to ensure the reliable recovery and smooth utilization of preheated steam. This technology has been applied to Hebei Puyang Iron and Steel Co., LTD and Hebei Dongshan Metallurgical Industry Co., LTD., and was successfully put into operation in 2007 and has produced considerable benefits.

二、System Features

A Energy saving - No matter SRT preheating power generation or high efficiency gas power generation, waste steam and waste gas generated in the process of industrial production are used, and no energy needs to be consumed in the system power generation process.

B efficient - SRT preheating power, by raising the quality of the steam parameters, efficiency can achieve 70% above, efficient gas power generation is a small generating set is usually used in medium pressure steam temperature parameters instead of high temperature and high pressure steam for power generation, by enhancing the steam parameters, the steam power efficiency can increase by more than 20%, This increases the power generation capacity of the entire system.

C Intelligent - system adopts ICS intelligent control system and DCS operating system, with the matching patent technology of SRT preheating power generation - steam filter voltage regulator device, can effectively control the pressure and flow of steam recovered from different production systems, so as to ensure the normal, stable and reliable operation of the unit.

D Environmental protection - The waste gas produced in the production process of the Colosseum enterprise, which is used in SRT preheating power generation and high efficiency gas power generation, condenses into water from the steam after power generation and is sent back to the kiln cooling system for recycling. In the whole system power supply process, not only the system itself has no pollution emission, but also can effectively reduce the environmental pollution caused in the production process of enterprises.

Innovative SRT high-efficiency power generation technology, we provide customers with natural gas, gas power generation engineering technical consulting and construction services - Hebei Huaye Energy Saving Technology Co., LTD

Energy saving -Innovative SRT high efficiency power generation technology, using waste steam and waste gas generated in the industrial process, the system does not need to consume additional energy in the process of power generation.

High efficiency - Improve steam quality parameters, power generation efficiency up to 78%, steam work efficiency increased by 20%.

Intelligent - The use of ICS intelligent control system and DCS operating system, SRT power generation technology, can obtain a stable steam flow, ensure the reliable operation of the generator set.

Environmental protection - SRT technology makes the steam condensed water after work recycled, no pollution of water sources, reduce environmental pollution.

三、Successful case

Puyang Iron and Steel Plant gas power generation,

Jinxi Zhengda Gas Power Plant,

Huaming Power Plant

Add: A6 Yigao ZhiNeng Squares, East Ring Road, Handan

Tel: 0310-3270200

Email:[email protected] [email protected]

Fax:0310-3270200

三、Successful case

Puyang Iron and Steel Plant gas power generation,

Jinxi Zhengda Gas Power Plant,

Huaming Power Plant

Add: A6 Yigao ZhiNeng Squares, East Ring Road, Handan

Tel: 0310-3270200

Email:[email protected] [email protected]

Fax:0310-3270200 Hebei Huaye Energy Saving Technology Co., LTD profile

Hebei Huaye Energy Saving Technology Co., LTD profile

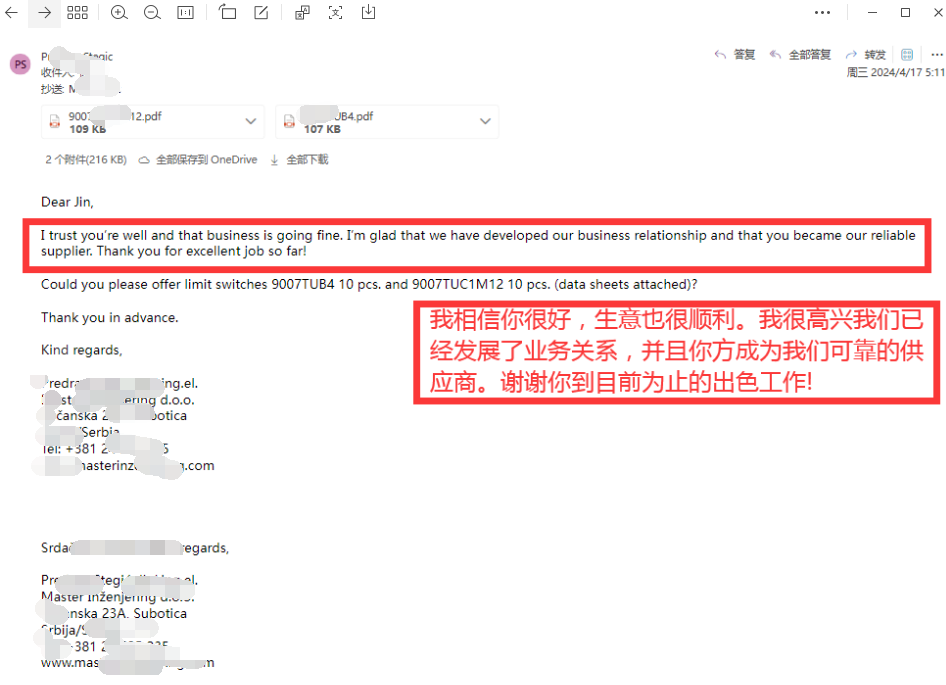

A thank-you note from a customer

A thank-you note from a customer

8000B MONITOR MODULE LIST

8000B MONITOR MODULE LIST

Nidec HS71-06400350A10100AB100 delivery today

Nidec HS71-06400350A10100AB100 delivery today

Order for Jiangyin Zhonghe monitoring module 8000B/12/32/42/72 and eddy current sensor DWQZ 25mm

Order for Jiangyin Zhonghe monitoring module 8000B/12/32/42/72 and eddy current sensor DWQZ 25mm